Focusing devices for pyroelectric infrared sensors

Pyroelectric infrared sensors

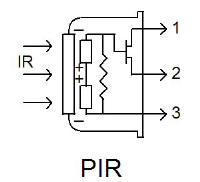

First we will look at a pyroelectric infrared sensor and see how it is made and why a focusing device is necessary. A commonly used pyroelectric infrared sensor has two sensing elements internally connected in a voltage bucking configuration.

|

A pyroelectric sensor has an infrared filter window that admits IR within the 5 to 15 micrometer wavelength range. One end of the two series-connected elements in an analog sensor is connected to pin 3 that is normally grounded. The other end connects internally to the gate of a Field Effect Transistor and to a very high value pulldown resistor. Power is applied to FET drain pin 1 and the output signal comes from FET source pin 2 which usually connects through an external pulldown resistor to ground and to an amplifier. A digital sensor not shown here, includes internal processing circuits and outputs digital pulses. |

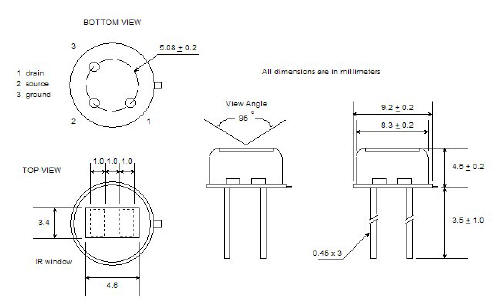

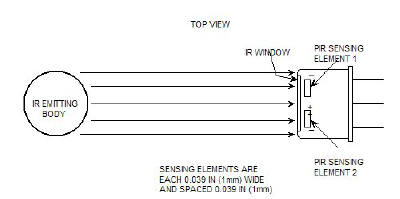

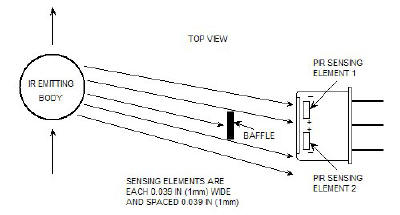

The sensor is housed in a TO5 type package. Sensing elements are each 0.039 inch (1mm) wide and are spaced 0.039 inch (1mm) apart.

|

Environmental conditions such as temperature changes and sunlight will affect both elements simultaneously and will produce the same amount of output from each element but of opposing polarity and will therefore be cancelled. The sensor will only produce a change in its output voltage when one of its elements is exposed to a change in radiation and the other is not exposed.

|

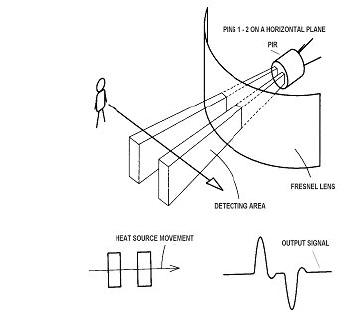

An IR emitting body moving across the front of a sensor will expose first one, then both and then the other sensor element. The output signal waveform from an analog sensor shows that for motion in one direction, first a positive, then zero and then a negative transition results. Motion in the other direction will produce first a negative, then zero and then a positive transition. |

When a lens is not used in front of a sensor and an IR emitting body is close to the sensor, about 3 or 4 feet and it moves across the front of the sensor, the radiated IR will expose one element more than the other and a voltage output will result. However, when the IR emitting body is further away from the sensor its radiation pattern becomes blurred and both elements are exposed more equally, resulting in no voltage output. The limited detection range is due to a lack of unequal exposure. Placing a lens in front of the sensor extends its detection range.

The Fresnel lens

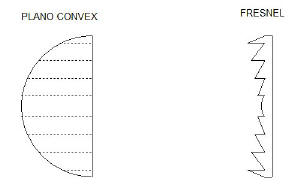

A Fresnel lens is a Plano Convex lens that has been collapsed on itself to form a flat lens that retains its optical characteristics but is much thinner and therefore has less absorption loss.

|

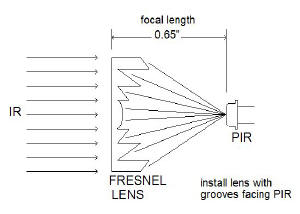

A Fresnel lens is usually thin and flexible and is about 0.015 inch (0.38mm) thick with grooves molded into one surface. The groove side of the lens usually faces the PIR sensor. |

|

A Fresnel lens both captures more IR radiation and focuses it to a small point. This focal point moves across the sensor as the IR source moves and exposes one element at a time. A Fresnel lens can extend detection range to about 100 feet. |

A Fresnel lens will give the best possible performance, however other devices can be used to extend range. Although the following devices may not fit the description of a lens, we will call them lenses anyway.

|

This diagram shows IR exposing both elements equally when no lens is used. |

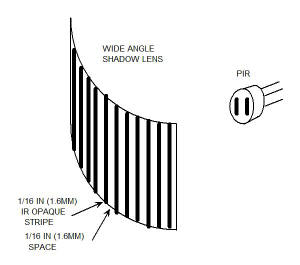

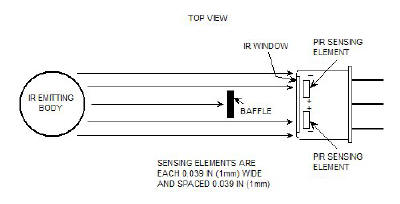

Shadow lens

Since simultaneous exposure of both elements is the cause of limited detection range, all we need is some method of preventing the IR from exposing both elements simultaneously as the IR emitting body moves across the front of the sensor, even at greater distances from the sensor. The sensor elements are 0.039 inch (1mm) wide and are spaced 0.039 inch (1mm) apart. If we place a thin vertical strip of IR opaque material about 0.060 inch (1.5mm) wide centered in front of the sensor we can prevent some of the IR from striking the surface of the sensor by producing a shadow, even if the IR emitting body is at a greater distance from the sensor. The following figure shows such a baffle but in this example the IR still exposes both elements equally.

|

By placing a baffle or mask in front of the sensor, we can block some of the IR and produce a shadow on the sensor |

This next figure shows what happens when the IR emitting body moves across the front of the sensor even at greater distances. The baffle allows full exposure of element 1 while blocking the IR so it produces a shadow over element 2 and does not expose it. This simple lens extends detection range up to 20 feet and is easily made from a strip of paper or other material. The baffle can be spaced 1/2 inch (12mm) to 1 inch (25mm) in front of the sensor. The greater spacing gives a narrower detection angle.

|

As the IR source moves, the baffle blocks it from exposing one of the sensor elements while fully exposing the other. |

This same idea can be expanded to produce a wide angle lens. Multiple baffle strips can be placed in front of the sensor to alternately block IR from one sensor element at a time even when the IR emitting body is at greater angles to the front of the sensor.

|

This multiple baffle shadow lens provides a wide detection angle. The lens should be curved so all baffles are the same distance from the front of the sensor. |

Pinhole lens

Another simple focusing device that will expose one PIR sensor element at a time can be made using a thin piece of IR opaque material with a hole in it that will function as a pinhole lens similar to the lens of a pinhole camera. The function of a pinhole camera lens is described in http://science.howstuffworks.com/question131.htm . The lens hole in a camera is usually small but can be much larger in a sensor application where image detail is not necessary and only the IR radiation from the animal must be focused onto one sensing element at a time. IR in the 5 ~ 15 micrometer wavelength range will not pass through most materials so you can make a lens of paper, plastic or metal foil. The hole should be about inch (6.4mm) diameter. Lens spacing is not critical but it should be about inch (12mm) to 1 inch (25mm) from the front of the sensor. A detection range of up to 20 feet can be obtained with this type of lens.

Although a narrow field of view is usually most desirable for animal photos, a wide field of view can be obtained by placing several holes in the lens material and curving the lens in front of the sensor so all holes are an equal distance from the front of the sensor. Another type of lens can be made by placing a tube about 3/8 inch (10mm) diameter and 2 inch (50mm) long over the front of the sensor. This lens will have a narrow field of view.

Infrared window

A pyroelectric sensor is very sensitive to rapid temperature changes. A rapid change in air temperature due to a breeze from an open window or from an air conditioner or heater can cause false triggering. The shadow and pinhole lenses described above do not offer protection against such air movement because they are actually open lenses. For outdoor use you would also need protection against rain.

An IR transparent weatherproof shield or window can be made of polyethylene which is transparent to IR radiation in the 5 ~ 15 micrometer wavelength range. Polyethylene can be identified by burning a small piece. It will burn with a mostly blue flame and melt like wax while other plastics that are opaque to IR will burn with a smoky red flame and leave a black ash. The only problem with polyethylene is that it is waxy and most adhesives will not bond to it but you can hold it in place with scotch tape, silicone rubber or hot melt glue.

Plastic milk bottles are made of polyethylene, and although it is whitish and not visibly transparent, it is transparent to IR with some small loss in detection range. The polyethylene milk bottle is thin, easily cut with scissors and makes a good IR window. Many food containers and plastic sheeting are also made of polyethylene. A thinner window will have less absorption loss.