Relays, The Electromechanical amplifier

A relay can be compared to a vacuum tube and solid state transistor amplifier because both can use a small voltage and current in one circuit to control a large voltage and current in another circuit. However, unlike tubes and transistors, a relay cannot produce a variable output; It can only switch on and off similar to a logic circuit in a computer. But the relay has the advantage of being able to completely isolate its input circuit from its output.

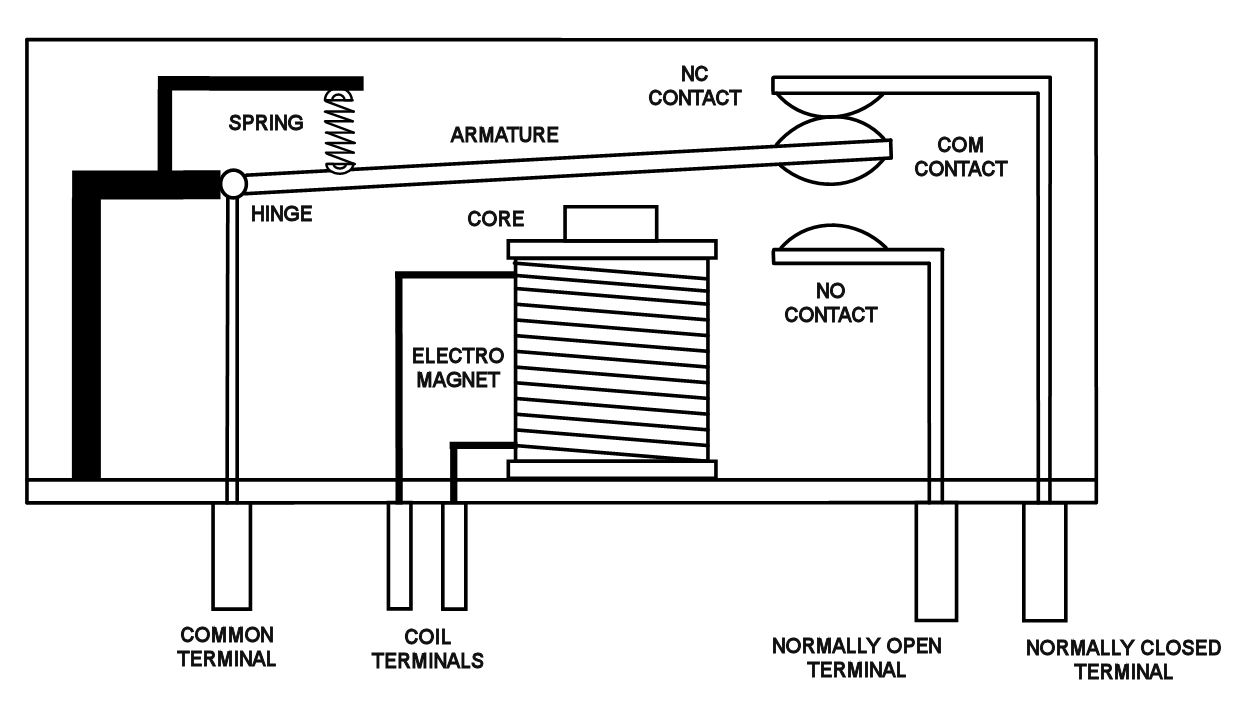

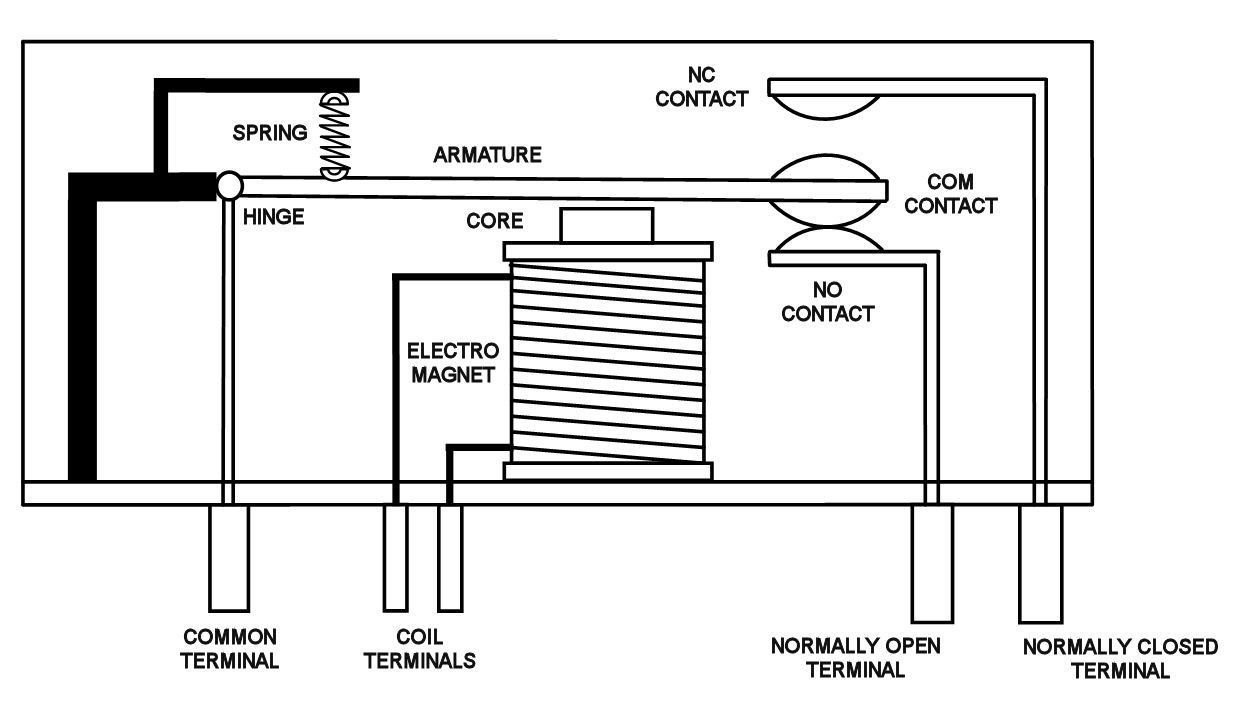

Below is a drawing of a Single Pole Double Throw (SPDT) relay. A single contact called the Common contact switches between a Normally Closed contact and a Normally Open contact. The Common contact is attached to an armature which is a strip of metal that is hinged at one end and has electrical contacts, usually made of silver, at the other end. A spring pulls the armature up so its contact connects to the Normally Closed contact. An electromagnet below the armature attracts the armature when it is energized and pulls it down so its contact disconnects from the Normally Closed contact and connects to the Normally Open contact instead.

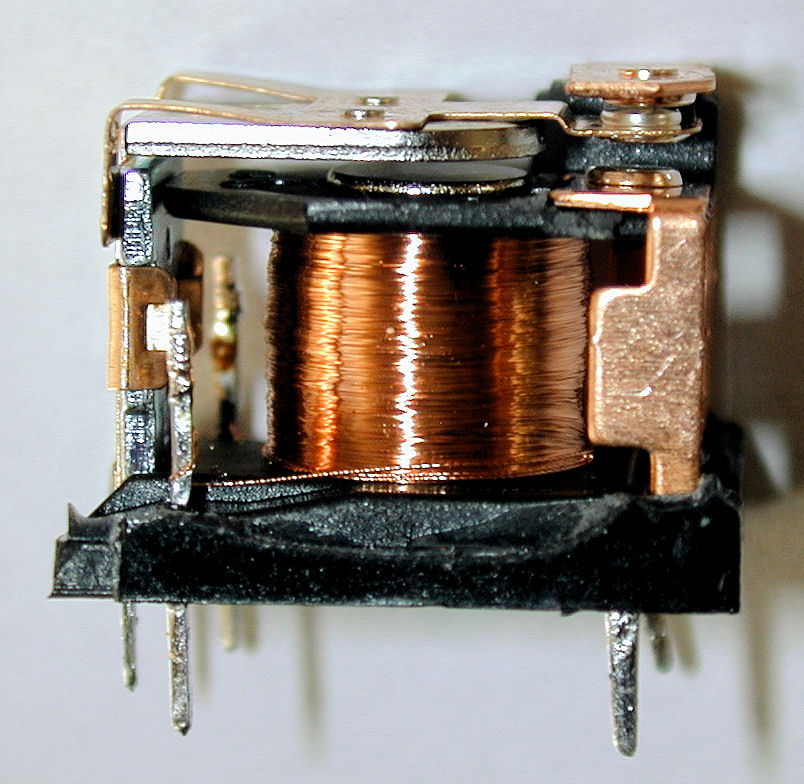

The electromagnet is made of a coil of fine enameled copper wire wound on a plastic bobbin that has an iron core in its center. A magnetic field is created in the iron core when current flows through the coil. The number of turns in the coil and the wire size determine the voltage that must applied to it. Relays are available for operation at almost any voltage but the most common are 5, 6, 9, 12, 24 and 48 volts DC. The coil current also depends on the number of turns and wire size and usually ranges from 30 to 200 milliamperes.

|

This is a drawing of a de-energized relay When no current is flowing in the electromagnet coil the armature is pulled up by the spring and its COM contact connects to the NC contact. |

|

This is a drawing of an energized relay. When a voltage is applied to the electromagnet coil the current flowing in the coil produces magnetic energy in the iron core which pulls the armature down. When the armature pulls down the COM contact switches from NC to NO. |

There is no connection between the coil and any of the contacts. The contacts are completely electrically isolated from the circuit that powers the coil.

In a device using a relay where the relay contacts are brought out to a terminal block or other termination, the contacts can be used to switch any type of DC or AC load that is within the voltage and current ratings of the contacts. This is usually marked on the relay.

A relay does not provide power for a load, it just switches power from a power source, on and off, similar to how a wall switch turns a lamp on and off but does not itself provide the power that lights the lamp.

|

Photo of a Single Pole,

Double Throw (SPDT) relay with its plastic housing removed. The coil is

wound of fine enameled copper wire wrapped around an iron core. This relay has a flat spring made of phosphor bronze instead of a coil spring. The flat spring also replaces the hinge used in some relays. The silver Common contact can be seen extending from the armature and resting against the Normally Closed contact above it. |

|

Relays are made in many configurations, sizes and shapes,

coil voltage and current, contact voltage and current. They are available

as: |

|

Single Pole Single Throw SPST either Normally Open or Normally Closed Single Pole Double Throw SPDT as above Double Pole Single Throw DPST either Normally Open or Normally Closed Double Pole Double Throw DPDT |

|

And other configurations. |